Zero-joint edgebanding is a trending technology, with its ability to deliver a seamless joint between edge and surface. The machinery required is a significant investment upgrade from standard edgebanders. But the approach means elimination of the glue pot – replaced by specially extruded edgeband material with an adhesive layer activated by hot air or lasers.

Zero-joint edgebanding is a trending technology, with its ability to deliver a seamless joint between edge and surface. The machinery required is a significant investment upgrade from standard edgebanders. But the approach means elimination of the glue pot – replaced by specially extruded edgeband material with an adhesive layer activated by hot air or lasers.

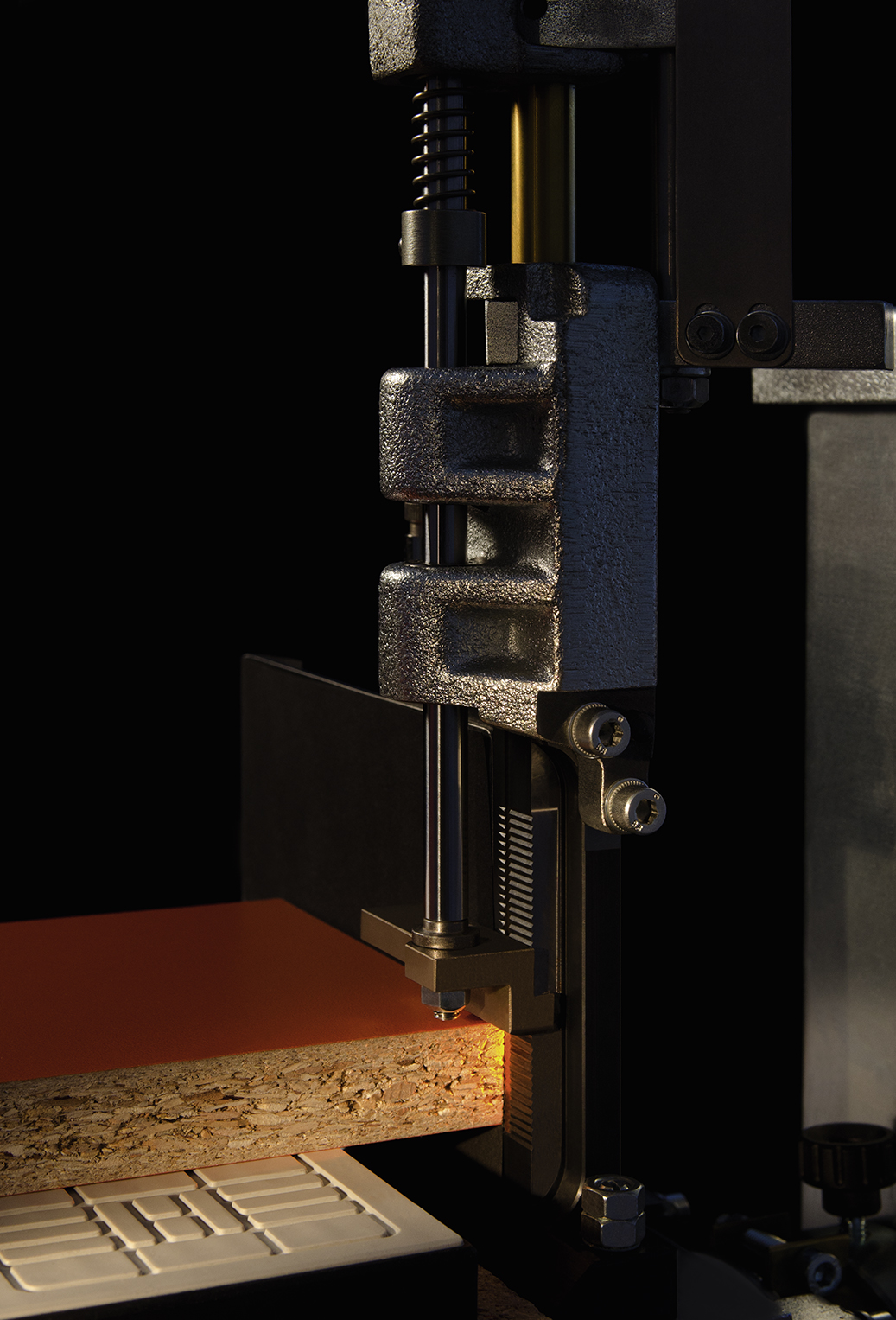

Holz-Her, advocating a third way, will bring to IWF 2014 its GluJet “melt-on-demand” adhesive application system for its edgebanders. Here’s how it works:

GluJet heats up in 3 minutes, uses conventional glue pellets, and meters the glue precisely – so no over-application that can lead to sloppy joints. This very thin glue line gives the “zero-edge” effect. Glue is melted in an air-tight chamber and delivered, under pressure, through an application nozzle. Because the glue is extruded, and delivered under pressure, it penetrates the fibers and fills all the voids in any workpiece. This makes the glue bond extremely strong and durable, Holz-Her says.

And because the glue is melted and delivered “on demand,” it is not re-circulated as on conventional glue pots, and so no smoke, fumes, or toxic vapors are released. Its sealed system also does not become contaminated by wood dust and other debris.

It has just three moving parts and no conventional gears, chains, bearings, rollers or other mechanisms. GluJet can use conventional granulated hot melt (EVA) glue, as well as cartridges, and multi-industry 2 kg slugs. It can apply glue in multiple colors with a 5-minute changeover. And it can apply both EVA and PUR adhesive as standard, with no specialized tanks. PUR can be left overnight with no risk to the system because it’s sealed.

Have something to say? Share your thoughts with us in the comments below.