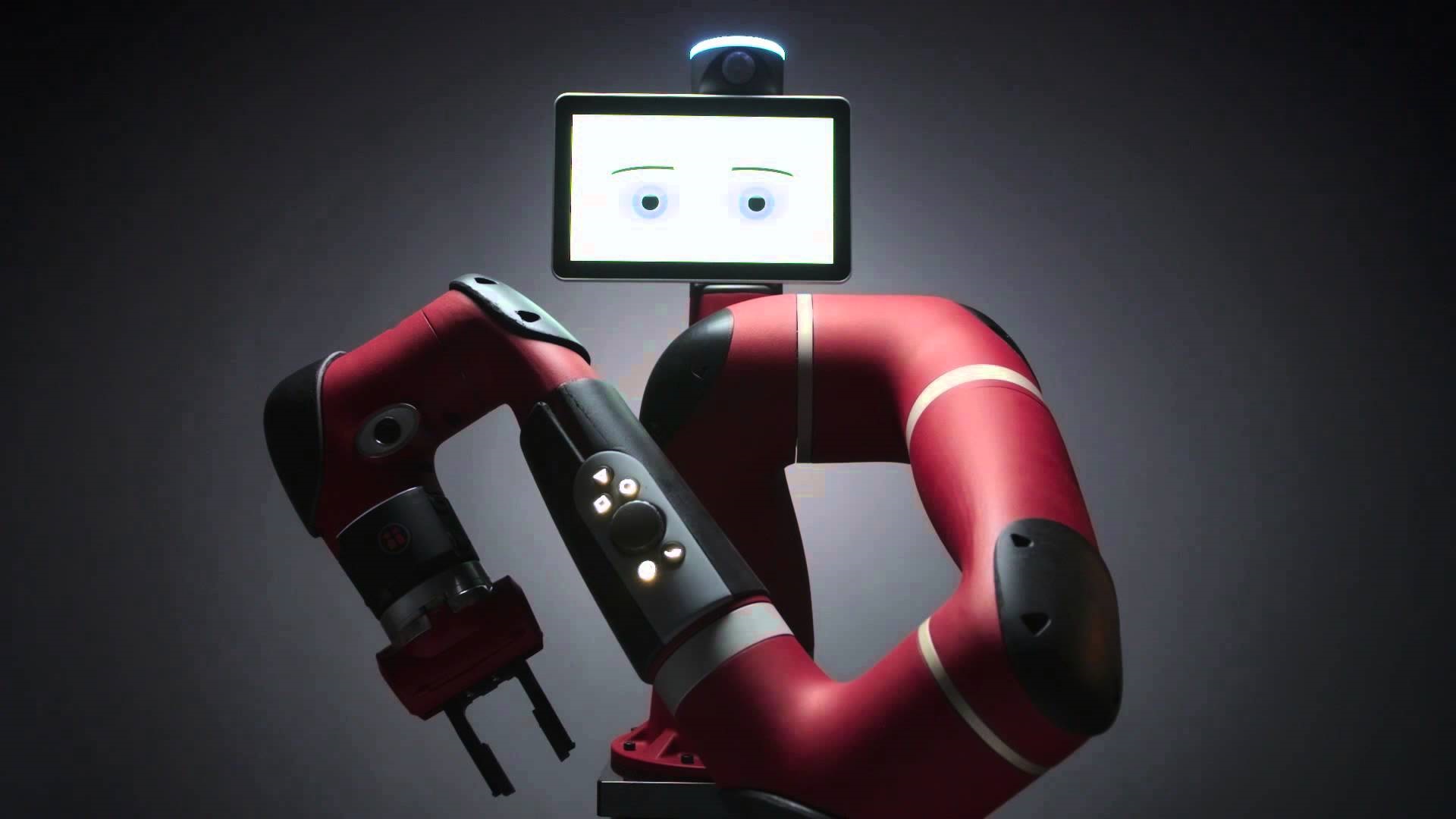

FITCHBURG, Ma. - Faced with a shortage of skilled workers, Moduform, a furniture manufacturer for colleges, libraries, healthcare facilities, military bases, detention and public safety spaces, has invested in Rethink Robotics' Sawyer robot.

Moduform deployed Sawyer to fill the gap in its current labor shortage, create better jobs for existing employees and meet market demands in the furniture manufacturing industry.

Sawyer is being used to assemble drawers at Moduform, sliding parts into a dovetail machine, retracting pieces and repeating until the drawer is complete.

Sawyer is currently being used in the work cell to help assemble drawers. Sawyer's versatility allows the robot to be used on various tasks to build the drawer, including picking up parts from the pick pallet, pushing them into place, sliding them into a dovetail machine, turning on the machine, retracting the piece and repeating the process until the drawer is complete.

Sawyer ensures each piece is aligned correctly and is the correct dimensions. Moduform's manufacturing engineer is quickly able to deploy Sawyer on different tasks based on what application Sawyer would be most helpful for on any given day.

"In the furniture business, many of the production jobs can be monotonous or temporary due to the seasonality of customer demand. Because of this, we can struggle with employee turnover and finding workers who are willing to simply pick up and put down parts all day long," said Josh Weissman, CEO at Moduform. "With Sawyer, we don't have to worry about finding people to complete these tasks. We can focus on recruiting workers for advanced work, such as cognitive jobs that leverage technology on the factory floor, and offer career advancement opportunities."

Moduform builds furniture for a wide variety of institutions. With such a diverse customer base, Moduform needs a flexible and durable workforce that can ramp up on orders quickly and meet seasonal market demands. Since deploying Sawyer, Moduform has been able to consistently adapt to and meet customer's needs by running longer operations and producing parts quicker.

[[{"type":"media","view_mode":"media_original","fid":"96112","attributes":{"alt":"","class":"media-image","typeof":"foaf:Image"}}]]

"Automation and robotics are changing our business. Like every company, we're constantly faced with the need to increase our efficiencies while closely managing our spending. If we can continually improve our processes, we can create better products," said Weissman. "Sawyer gives us the ability to deliver orders without excessive downtime, as well as allocate more resources to being more innovative and creative on the factory floor – which ultimately moves our business forward."

Moduform was founded in 1976, and the company buys parts and services locally while selling finished product internationally. The company has locations in Massachusetts and North Carolina.

"Globally, manufacturers are seeking solutions that allow them to affordably cater to changing market demands. In such a competitive industry, having solutions that allow them to stay innovative and create their products efficiently is a huge win," said Jim Lawton, chief product and marketing officer at Rethink Robotics. "However, many manufacturers have to allocate excessive time and resources to finding workers for their factories. Our collaborative robots offer a solution that closes the labor gap and allows manufacturers to deploy flexible automation, so they can stay competitive in an everchanging market."

Sawyer was developed by Rethink Robotics, whose goal is to transform the way manufacturing is done. With smart, collaborative robots able to automate nearly every task, manufacturers of all shapes, sizes and industries get the fast-to-deploy, easy-to-use and versatile automation solution they need to increase flexibility, lower cost and accelerate innovation.

Have something to say? Share your thoughts with us in the comments below.