The Weinig Group will underline its "Technology Offensive 2015" at LIGNA in Hall 12 with a range of innovations. At the center will be the introduction of new generations of technology.

The core themes will be resource efficiency, flexibility and networked production. In addition to the major premieres, there will also be pioneering developments on shows in the product unit Profiling as well as in the window manufacturing, cutting/gluing and joint technology segments.

The core themes will be resource efficiency, flexibility and networked production. In addition to the major premieres, there will also be pioneering developments on shows in the product unit Profiling as well as in the window manufacturing, cutting/gluing and joint technology segments.

Furthermore, Weinig will be demonstrating its expertise as a complete provider of machines and systems for solid wood processing. Weinig Concept, the engineering arm of the company, will be presenting system technology through to complex production lines. In the immediate vicinity of Weinig's solid wood processing stand, the business unit Panel Processing will be exhibiting its range in Hall 11. Holz-Her will be in Hanover with innovations in edge banding, CNC processing centers and panel cutting.

|

| For information on Ligna, click here |

Premiere for the new Powermat series

In the Powermat 700 and Powermat 1200, Weinig will be revealing the new Powermat generation to the global audience in Hanover for the first time. The outstanding feature of the moulder is the innovative "Comfort Set" operating concept, which enables largely tool-free setting and significantly reduces set-up times. Further benefits of the four-sider include high operating safety and very good accessibility. It also impresses with its high energy efficiency, which is primarily attributable to the optimization of the extraction system.

Particular progress has been made with the optimized flying of chips. The chips are better removed, reducing the risk of chip impact against the wood and tool. The "Smart-Touch" function makes the new Powermat a trendsetter in man-machine interaction in wood processing. Wireless communication, for example, is possible between controls or tablet and the machine. This way, information on set-up is displayed to the operator where he needs it. Smart Touch will be demonstrated at LIGNA on the Powermat 1200 model.

New: Networked production with System Plus

The new Weinig System Plus connects all processes involved in preparing the moulder for production. The integrated system is comprised of the Moulder Master Software, the new Rondamat 1000 tool grinder, tool measurement with OptiControl Digital and PowerCom machine controls. From creating drawings in the integrated 2D CAD program, straight and profile knives are produced with the fully-automated CNC grinder based upon the data provided. Reference points are then measured via a camera system using images supplied by the Moulder Master.

Finally, the data is transferred to the PowerCom machine controls for setting up the machine. Weinig System Plus offers networked production from a single source and reduces throughfeed time by reducing the process stages. Risk of errors and downtime is also reduced via optimal work preparation.

New: Rondamat 985 tool grinder

In the Rondamat 985, Weinig will be exhibiting a new grinder in Hanover for straight knives with max. 720 mm tool length. The Rondamat has a grinding unit with fully-automatic controls and integrated radius measurement of the knives. It is ideal for precise grinding of drilling tools, knife shafts and hydraulic tools. The latter particularly enables the precision of the Rondamat 985 to extend the intervals between tool changes via jointing.

New processing units and tool clamping systems for the Conturex CNC window center

For as long as there have been wooden windows, the corners and connections of the horizontal and vertical transoms, mullions and glazing bars have been the most sensitive areas. The quality of these connections stands and falls on the gluing and the precision of the transversal and longitudinal processing. Besides the conventional methods, such as mortise-tenon and dowel connections, the new, highly robust round tenon corner joints are increasingly establishing themselves in the windows and doors market. The initial results show a material improvement in terms of the bending and breaking strength of these connections. Manufacturing these corner joints is almost exclusively restricted to CNC centers. The concept of the Weinig Conturex with its open and flexible configuration is precisely tailored to round tenon production. Using new processing units and tool clamping systems, the Conturex achieves optimal precision and productivity. Even producing a mix of different connections is not a problem.

New: "Nocturnal" tool cleaning station

The condition of tools has a significant influence on service life and wood surfaces. The effect of the different wood types, particularly softwood, on tool blades is often completely under-estimated. During milling, layers of resin and glue are built up that become stuck in the chip area and on the tool body. These build-ups and deposits in the chip area normally have serious consequences for service life and particularly for surface quality and even result in increased power consumption. Tools on CNC systems work with significantly higher speeds than on conventional machines and, therefore, react more sensitively to the afore-mentioned influences. The result is increased imbalance and uneven chip removal.

Regular cleaning of valuable tools is, therefore, highly recommended for reasons of cost-effectiveness. The level of care is adapted to the condition of the tools. Once again, Weinig has shown the spirit of innovation here. A fully-automated tool cleaning station with program control takes care of this. At night, during free shifts or at weekends, the wash system takes the relevant tools, cleans them and returns them to the appropriate changeover position. A change of cutter or sharpening is then also problem-free.

New generation of the UniPin gluing and dowel inserting machine

With the new user interface and performance-enhancing process optimization, Weinig is entering the next generation of the UniPin gluing and dowel inserting machine. Whether online in contact with the Conturex or as an individual machine, the new and improved Weinig UniPin is an indispensable CNC system. On a double-leaf window with central pillar and counter-corner or dowel corner joint, at least 56 dowels can be inserted. This means a daily capacity of 1,120 dowels with 20 windows. And all with consistent quality and, crucially, precisely the same glue amount and insertion depth. Only thus can high-quality connection of window corners be guaranteed. The new generation is equipped with new, rapid controls and optional double part processing. In addition, a significantly improved user interface has been developed.

New: "Block gluing" production concept

New: "Block gluing" production concept

The Weinig Concept business unit specializes in project planning of complete production lines. A current project will be presented at LIGNA as an example. Visitors to the Weinig stand will be able to learn everything about the project from planning to installation of the system. The system solution comprises an innovative production process for central layers. Weinig has patents and patents pending on the "block gluing with butt joints" process. With this process, Weinig is setting standards in efficient use of resources. Whether planing, gluing, cross-cutting or ripping, technologies are used that create significant savings and higher wood recovery. Block gluing is also more reliable and far less expensive than conventional processes. The added value potential starts with the round timber cutting as block gluing allows the use of a range of sawn timber dimensions with the same end product.

The high flexibility of the system also opens up a range of other products, starting from the glued block, including top layers, shafts for timber construction, CLT profile lamellae and even door frame blanks. The centerpiece of the system, the ProfiPress C, presses the glued butt-jointed strand without height offset and with perfect alignment in length. The ProfiPress C is designed for special application as a cold press and, thus, requires no energy for glue hardening. With excellent pressing force distribution, the required adhesive volume can be reduced to a minimum.

New: Standard Weinig user interface

The new standard user interface for all Weinig machines will be shown for the first time at LIGNA. The interface has been developed to offer the user consistency in operation and menu navigation across the entire Weinig product portfolio. This means that the individual machines and software applications create a perfect unit that works together optimally.

The intuitive operation is easy to learn. At LIGNA, the new user interface will be on display with optimizing cross-cut saws from the Dimter Line and Optipal packer software.

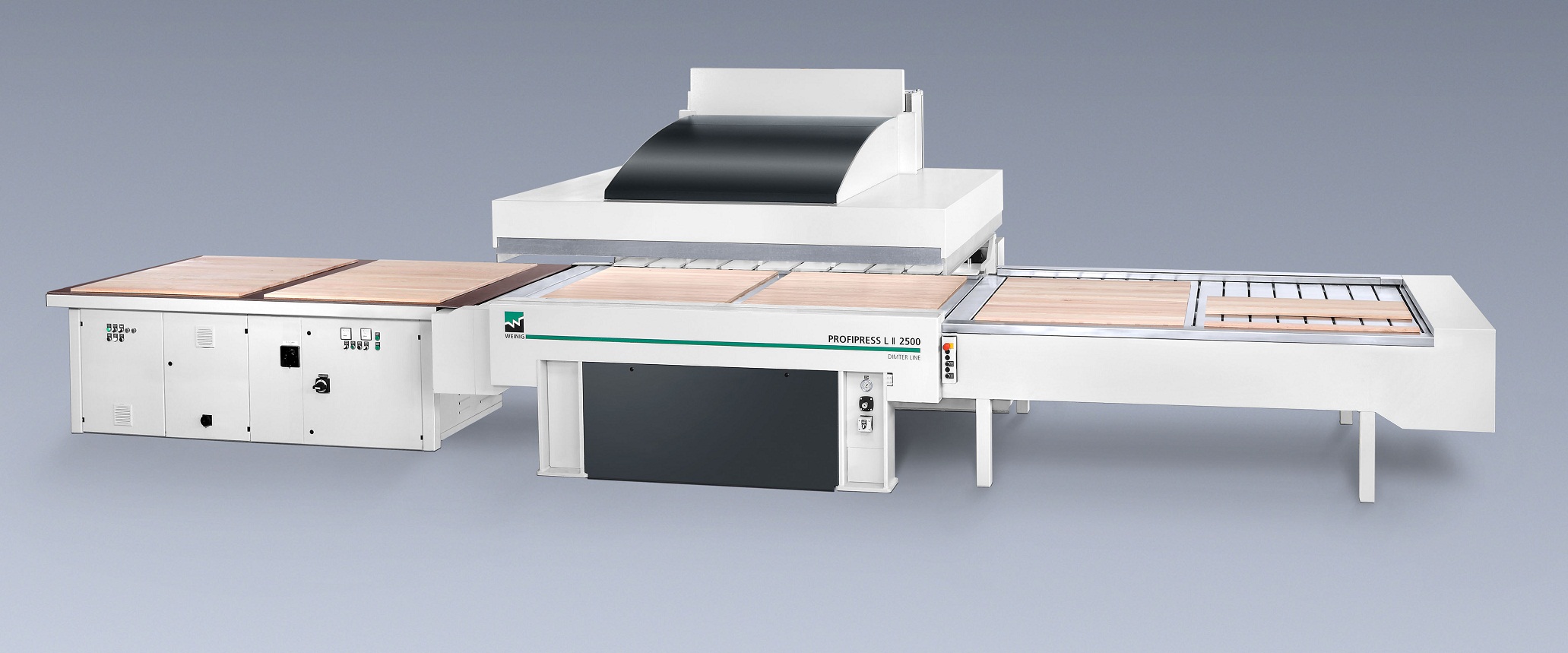

New: ProfiPress L II gluing press

New: ProfiPress L II gluing press

The new Weinig ProfiPress L II is primarily aimed at ambitious workshop businesses and is designed for one-man panel production. The degree of automation of a machine is the basis of personnel efficiency. Both the positioning of the glued lamellae and transfer of the lamellae from the gluing station to the infeed belt or infeed chain are automatic. The pressure cylinders are also selected automatically. The ProfiPress L II proves its worth in high-capacity layer formation and impresses with the perfect calculation and positioning of the track, which is also guaranteed with multi-track operation.

Cutting solutions: intensive upgrade

The extensive Dimter Line range of cross-cut saws from Weinig has been enhanced with a range of improvements and extensions in time for LIGNA. The OptiCut 200 Elite, which will be on the stand in Hanover as an Inline scanner solution with EasyScan, will enjoy a product re-launch. A new design, new and larger touch-screen user interface and performance-optimized machine concept will all enhance the attractiveness of the cross-cut saw.

For the OptiCut S 50 Window, the alignment aid for packages in the infeed table is also now available. The popular option of the OptiCut S 90 series provides for increased length accuracy and process reliability. The options for workpiece recognition have also been extended for models from the OptiCut S 50, OptiCut S 90 and OptiCut 450 FJ+ series. The range now extends from simple recognition of workpieces to application of high-definition graphic logos even at high feed speeds in the outfeed of an OptiCut 450 Quantum or FJ+. In addition to the increased degree of automation, the advantages lie in optimal process reliability and value creation. Also at LIGNA, a system solution will be exhibited for the first time that builds upon the OptiCut S 90 Speed. This cross-cutting system for pure defect removal achieves performance that can otherwise only be achieved by throughfeed saws while also impressing with its high length accuracy.

New: ProfiRip 340 multi-blade buzz saw

The completely newly developed machine offers up to 3-fold blade adjustment and is designed for a high level of productivity. The TimberMax software ensures particularly high wood recovery. The quality optimization in 2D taken into consideration the required part lengths during separating. Minimal set-up times and high user-friendliness are among the other attributes of the ProfiRip 340. This includes the Quickfix quick clamping system, which allows the fixed saw blades to be clamped without tools. The exemplary safety standard of the saw is assisted by the SafetyPlus concept and the new "Chain Protect" to protect against inadvertent "sawing into the chain".

New: RipAssist Pro width optimization

The proven RipAssist optimization program for automatic width optimization of boards now offers even better performance. In the enhanced "Pro" version, the board width is now automatically measured with trimmed goods. The software itself has been given an upgrade and can now also optimize combinations of fixed arbor set-ups (several fixed saw blades) and adjustable saw blades. It is now also possible to take into consideration variable strip widths. This means even greater material yields. Automatic measurement also increases productivity. The new RipAssist Pro can been seen at LIGNA along with the VarioRio 310 multi-blade rip saw.

Optimal value creation: ProfiRip 450 Speed with CombiScan

Profit maximization and quality start with cutting optimization. At LIGNA, Weinig will be demonstrating its expertise in this process with a high-end system consisting of a ProfiRip 450 Speed separating saw and a Weinig CombiScan scanner. The ProfiRip 450 Speed with roller feed is designed for speeds up to 160 m/min. It has 4-fold blade adjustment and a saw shaft with outboard bearing. Pneumatic clamping ensures tool-free operation.

New: GlueEye glue detection system

The new GlueEye glue detection system offers visual inspection of glue application for HS systems. The current glue application is compared for coverage with a prepared master image using color cameras. Lamellae with defective gluing are indicated on the touch panel and rejected based upon defined tolerances. The finger-jointing line stops after a pre-selected number of successive defective gluings. GlueEye can also improve quality since knot holes, broken pieces of wood, under-sized or over-sized pieces of wood and broken finger joints can be at least partially detected and discharged. A GlueEye for package lines is in development.

New: Trimsaver for package lines

The Trimsaver, which is already successfully in use with Weinig horizontal finger-jointing lines, is now also being developed for package lines. The Trimsaver measures the workpiece on the front side before positioning it such that a little wood as possible is machined before the finger joints are milled. This allows wood savings of up to approx. 60,000 running m/year, equivalent to a profit of €50-100,000. Other advantages of the Trimsaver are reduced tool load as well as reduced chips and hence lower disposal costs.

New generation of long-timber finger-jointing lines

The new generation of Weinig's long-timber systems will be presented via animation at LIGNA. The concept is scheduled for market launch in the near future.

Double-end tenoner: Next stage of evolution for the ProfiShape

At Ligna 2013, the premiere of Weinig's ProfiShape captured the limelight. Two years later, the double-end tenoner will be back on the stand in the next stage of its evolution. The customer system on show has magazine charging that can be swung away and is set up for 50 parts/min to create a tongue and groove profile. The machine is equipped with 2 trimming units and 3 milling units on each milling side. The motorized adjustment of the right-hand machine side achieves higher machine availability. Automatic chain cam control changes the cam distances according to the material width. The servo positioning that adjusts itself to the material thickness is also automatic.

Finger-jointing system range: Presentation in Alfeld/Leine

In parallel with LIGNA, Weinig will be exhibiting additional finger-jointing systems at the Grecon factory in Alfeld. The short-timber finger-jointing lines ProfiJoint Comfort, Ultra TT 1000, CombiPact Capacity, Turbo-S and HS 120 will be on display only 30 kilometers or so from Hanover. These will also be joined by the PowerJoint 8 long-timber finger-jointing system and a double-end tenoner: ProfiShape.

Have something to say? Share your thoughts with us in the comments below.