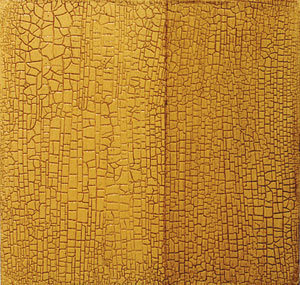

I know of three different methods for “crackling” a finish: ready-to-use crackle coatings, “crackle mediums” and liquid hide glue, made from animal hides and bone renderings. With each of these methods, the thicker the application, the larger the crackle, and the thinner the application, the smaller the cracks. Regardless of method, crackling is an extremely random and unpredictable process, affected by temperature changes, moisture content, variations in materials and the differences in their applications.

I know of three different methods for “crackling” a finish: ready-to-use crackle coatings, “crackle mediums” and liquid hide glue, made from animal hides and bone renderings. With each of these methods, the thicker the application, the larger the crackle, and the thinner the application, the smaller the cracks. Regardless of method, crackling is an extremely random and unpredictable process, affected by temperature changes, moisture content, variations in materials and the differences in their applications.

Ready-to-Use Materials: These come in different colored basecoats and crackle topcoats. There also is a ready-to-use water-clear crackle coating. These coatings are straightforward to use: you apply the base color coat, allow it to dry, then spray the colored crackle coat and allow it to dry overnight. Then you apply a compatible water-clear coating to preserve and protect the crackle finish.

Crackle Mediums: These mediums are formulated for brushes or rollers and are compatible with latex paints or other water-base coatings. After the crackle medium is applied over a dried coating, it should be allowed to set up, which can take between 1 and 3 hours. The shop temperature should be 55F to 75F.

The small type of crackle medium can be applied over stained, painted or sealed woods. Once it is applied, it will crackle on its own. It should be allowed to cure for a few hours; then a colored glazing stain is wiped and brushed out. Once the glaze is dry, it is clear-coated.

The large crackle medium must be used over a dry color coating. The crackle medium should be dry to the touch, but do not allow it to cure. Once it reaches that stage, it can be coated over with different colors of a flat latex paint. This coat activates the crackling and allows the base color to show the crackle pattern.

Liquid Hide Glue: The liquid hide glue is applied over a dried base colored coating and can be thinned out with hot water to reduce its viscosity. If you are working on larger pieces, a pinch of table salt can be added to the glue to retard the drying time.

Set-up time is approximately 1 to 2 hours, depending on the shop conditions. Once the glue is dry to the touch, but not cured, it can receive the color coat. After the colored topcoat is applied, crackles will appear gradually. The finish should dry overnight before applying a water-clear coating.

Source: Mac Simmons is a freelance writer and veteran of the furniture finishing, refinishing and restoration trades. For additional finishing articles, visit WoodworkingNetwork.com.

For suppliers of finishing and sanding equipment and materials, visit RedBookOnline.com

Click here for complete access to the comprehensive RedBookOnline.com

Have something to say? Share your thoughts with us in the comments below.