Regardless of the size or type of the shop — cabinet, casegoods, furniture, components, etc. — it is important to consider the following when selecting dust collection equipment:

Regardless of the size or type of the shop — cabinet, casegoods, furniture, components, etc. — it is important to consider the following when selecting dust collection equipment:

1. It is important to size the collector adequately for its intended task in both volume (CFM) and in suction power, known as static pressure (SP). Beware that the performance of small portable collectors may be overstated and misleading, and don’t be misled by high horsepower. A 5-HP collector with a 5-inch inlet is not going to give you performance in the 1,500-2,000 CFM range that an industrial type system will, so look to the inlet size for guidance. For example, a 5-inch duct at a typical 4,000 feet per minute (FPM) velocity will handle 546 CFM or perhaps 818 CFM at a more extreme 6,000 FPM velocity. (CFM= Velocity x Area of the pipe in square feet. Area = π r2/144).

2. Consider the machinery arrangement relative to the collector location. A simple, short duct system with a minimum of elbows and hose makes for maximum efficiency. Resistance to flow is greater per foot in the smaller diameter duct sizes and less in the larger diameters. Locate machines needing smaller ducts closer to the collector, and those needing larger ducts at the end.

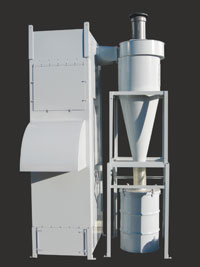

3. Plan for adequate dust and chip storage capacity, as well as how you will dispose of the waste. A small canister or single drum may not be workable for even a small shop if there is a machine that can fill a drum in minutes. Handling and transferring of collected dust indoors may also create a secondary safety, health and housekeeping problem. Consider an outdoor collector location, and whether you will recirculate the air from an outside afterfilter, or locate a cyclone outdoors and afterfilter indoors. Use of a cyclone pre-separator removes about 95 percent of most wood dust and chips prior to the filter, greatly reducing the filter load and increasing efficiency.

When handling combustible dust, always follow safe practices and install in accordance with all regulations and standards such as NFPA and OSHA. Fans should have non-sparking aluminum fan wheels and/or be located out of the dirty air stream. Construct the duct from conductive materials and ground it to dissipate static electricity.

Source: Richard Olsaver, vice president Aget Mfg. Co.

For more information visit AgetMfg.com or call (800) 832-2438.

For dust collection suppliers, visit RedBookOnline.com

Click here for complete access to the comprehensive RedBookOnline.com

Have something to say? Share your thoughts with us in the comments below.