Tooling development has made major steps forward in the last 25 years. Manufacturers have come up with sophisticated tool design and cutting materials, as well as improved quality and reliability of tools. These developments greatly expanded options for manufacturers in their choice of workpiece materials; noise levels could be reduced and tool performance was pushed. Tooling producers even researched peripheral areas such as the interface to the machine, which brought new tool holders (e.g. HSK tool holder and hydro sleeves) and spindle designs with accuracy and efficiency never seen before (high precision HF spindle). In their effort to optimize tooling performance, R&D departments widened research beyond the tool to include teams comprised of universities, machine manufacturers, raw material producers and tool users to find solutions for very complex problems like dust extraction.

It's a well-established fact that dust extraction impacts tool performance. In certain cases, chips created during the cutting operation can even cause an indentation on the workpiece surface (i.e. when workpiece chips are rotating a full 360 degrees with the tool and hit the finished workpiece after the cut). Optimized gullets, designed with the help of stroboscopes, contribute to minimizing this problem. Additional considerations are air speed and hood design. Insufficient air speed and hood design can cause a cloud of chips in the dust hood in which the tool rotates. Rotating cutting edges frequently hit bouncing chips, causing additional tool wear and accelerating the dulling process, thus reducing tool life.

Steps taken to improve this situation include repositioning of the evacuation nozzle—which results in the benefit of kinetic energy from the chips when they are cut off the workpiece. In other words, the dust hose nozzle is lined up in the direction from which the tool throws the chips, forming a funnel which collects most of the chips. A huge advancement.

Even with these improvements, however, dust is still not always extracted at a sufficient rate. Fine dust poses the biggest challenge—requiring frequent machine downtime for cleaning and maintenance (Illustration 1).

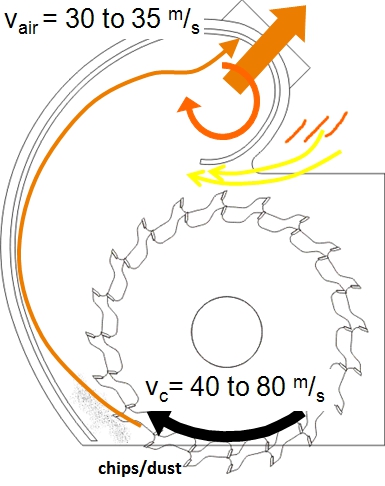

Looking deeper into dust hood design, researchers found that the minimum air speed in the nozzle area commonly requested by machine manufacturers was about 20m/s. Measurements in the field showed that the air speed is often much better—approximately 30-35m/s. However, this is still not sufficient when considering the speed at the outside diameter of a rotating tool (usually 40-80m/s). Comparing both speeds, the rim speed of the rotating tool and the air speed at the nozzle, there is more air brought into the hood (by the tool) than removed (through the air current in the dust hose) (Illustration 2).

Large workpiece widths often totally or partially cover the hood intake area (Illustration 3) by closing the open side of the hood. Obstruction of air intake is the consequence—the air flow breaks down!

The result is stagnation of pressure in the smallest section where the distance between tool and the dust hood wall is the smallest (marked H for high pressure) and a negative pressure in the collection nozzle area (marked L for low pressure). This stagnation pressure causes dust and chips to hit an "air cushion", preventing the proper removal of the particles (Illustration 4).

Dust hoods of a new generation are designed to avoid these areas of differing air pressure. Characteristics of a successful hood design are a curved guide in the area of chip flow, where the cross section between hood and tool continuously increases in the direction of air flow. A swirl section close to the nozzle helps guide uncollected chips back into the air stream. To avoid negative air pressure caused by this swirl, an air intake has been added. It allows a supporting air stream from outside into the hood (Illustration 5). The result is that over 95% of the particles created by the tool can be collected by this new generation hood.

The one known disadvantage of this technique is that it only works well when tool and hood design are coordinated. It would not be an effective solution for a shaper, where tools of different diameters and shapes are constantly exchanged. Excellent examples for successful use of this evacuation technique can be found in various applications involving laminate flooring, cement fibre board, gypsum board, XPS foam, MDF, particleboard, and even solid wood.

Source: Leitz Tooling Systems Inc. Visit LeitzTooling.com or call (800) 253-6070.

Have something to say? Share your thoughts with us in the comments below.