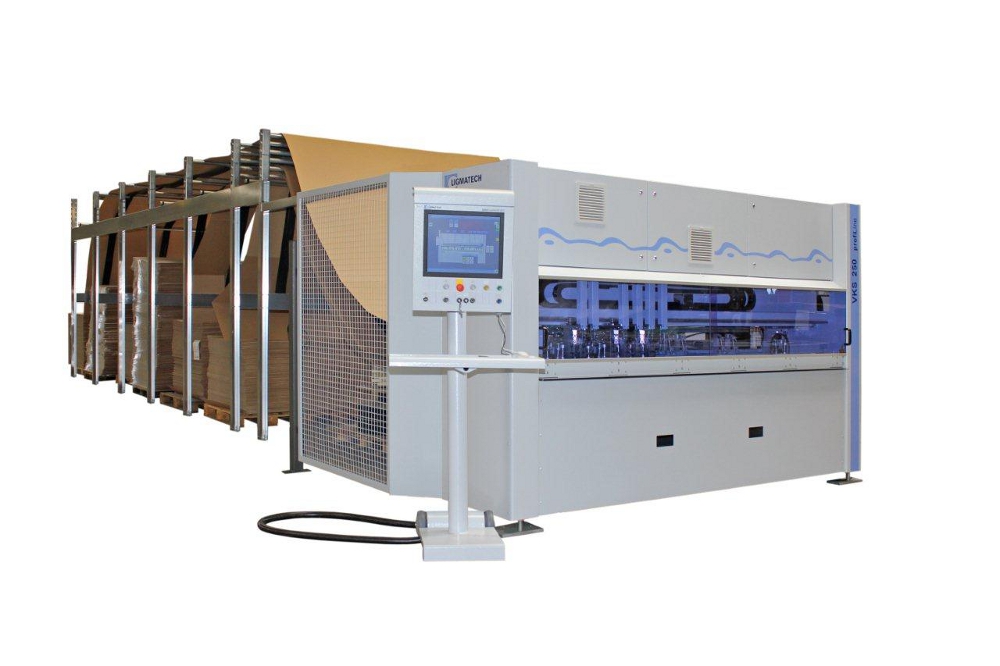

Whether ready-to-assemble furniture or completely assembled carcasses and fronts – the high-flexible cardboard cutting machine VKS 250 from LIGMATECH produces the custom-fit packing. Always in the optimal dimensions, in the required capacity and just-in-time. Moreover, the customized packing guarantees that the products are perfectly protected on their way to the customer – and by the way economically friendly.

The cardboard cutting machine VKS 250 automatically cuts packages made of corrugated board at the push of a button. Various tool configurations allow the customized manufacture of cardboard products for every type and size of products. LIGMATECH developed this new generation of cardboard cutting machine in cooperation with the company PACKSIZE.

The cardboard cutting machine VKS 250 automatically cuts packages made of corrugated board at the push of a button. Various tool configurations allow the customized manufacture of cardboard products for every type and size of products. LIGMATECH developed this new generation of cardboard cutting machine in cooperation with the company PACKSIZE.

Savings of up to 35 % in the packing sector

Focused on efficiency: The just-in-time production considerably reduces the storage costs and logistic activities, decreases the packaging times and optimizes the product protection. "More and more customers are convinced and rely on this solution," emphasizes Laurent Heimen, Sales Manager of the LIGMATECH company.

Reduction of storage and logistics charges

Today's product variety in the companies leads to the storage of a multitude of pre-assembled cardboard products of very different sizes. The result: high storage and logistics costs, such as p.e. imputed rent, heating, power or storage loss. In addition, high logistics expenses are created, which specially preponderate when small batch sizes are produced.

Today's product variety in the companies leads to the storage of a multitude of pre-assembled cardboard products of very different sizes. The result: high storage and logistics costs, such as p.e. imputed rent, heating, power or storage loss. In addition, high logistics expenses are created, which specially preponderate when small batch sizes are produced.

The VKS 250 enables it: On account of the just-in-time production of tailor-made packing a good percentage of these costs are omitted as only the raw stacks of the endless corrugated board are to be stored.

Reaching the target safely and efficiently with packages made of corrugated board

Despite a variety of pre-assembled cardboard boxes, quite often the optimum cardboard size is not available for every product.

As a result, additional filling materials are required to fill the voids in order to protect the products. Tailor-made packing designs, however, find a remedy as they offer an optimal packing of the products without any additional filling materials. Thus, expensive transport damages do not appear at all. Another advantage: The packing consists of one material and does not have to be expensively separated for correct recycling.

Environmentally friendly packing with LIGMATECH

By nature, corrugated board is sustainable and does not only connect ecological but also economical advantages. As pure natural product, corrugated board mainly protects the resources, can be easily disposed of and it can be completely and cheaply recycled. The good adaptability to the product and the low weight of corrugated board support the optimal utilization of storage and transport space. LIGMATECH also relies on corrugated board and thus contributes to the protection of the environment by means of the cardboard cutting machine VKS 250.

By nature, corrugated board is sustainable and does not only connect ecological but also economical advantages. As pure natural product, corrugated board mainly protects the resources, can be easily disposed of and it can be completely and cheaply recycled. The good adaptability to the product and the low weight of corrugated board support the optimal utilization of storage and transport space. LIGMATECH also relies on corrugated board and thus contributes to the protection of the environment by means of the cardboard cutting machine VKS 250.

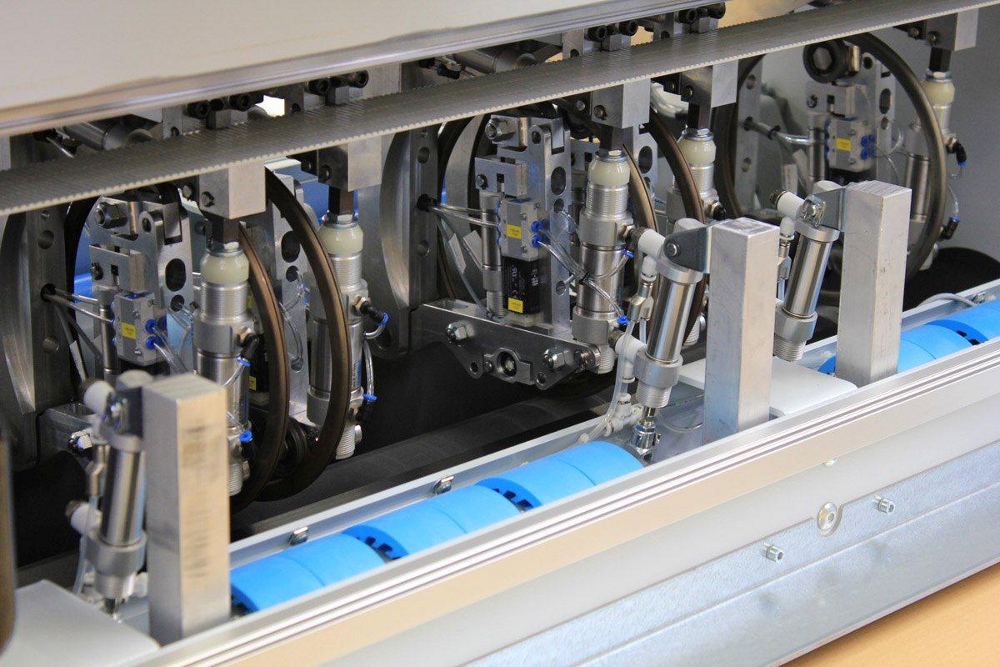

Multi-functional cutting tools: Convincing quality

Modern multi-functional tools allow cutting, corrugating and perforating at one point (single-point-principle). This process mainly saves time, as time-consuming setting of the tools is no longer required. The high cutting quality is guaranteed by using toothed cutting tools. Thus, the final manual or automatic folding and closing of the cardboard packaging are considerably facilitated. Moreover, cutting on rubber-covered rollers extends the tool service life. Another advantage: The cutting tools are quickly and fully-automatically set, which guarantees a high flexibility and higher productivity.

Innovative technology: simply flexible

Whether series production or batch size 1, whether single-sheet feeding or fanfold corrugated board, whether as stand-alone operation or integrated into a complex packing line – the cardboard cutting machine VKS 250 totally flexibly adjusts to the customers’ requirements. Mainly at batch size 1 production different product dimensions are normal. No problem for the VKS 250, which can be equipped with up to six cardboard feeding magazines. Special feature:

Depending on the demand, up to six different material widths (max. 2.500 mm) are available for the production of the packaging. This is an enormous advantage, as the time-consuming setting of the fanfold corrugated board is not required anymore, leading to an increased capacity.

The machine grows along with its challenges: depending on the demand, the VKS 250 can be individually complemented with a folding machine, a closing machine or a robot stacker and thus extended to a complete packing line.

Machine competence for flexible packing solutions

With a high competence for problem solutions and more than 20 years of experiences LIGMATECH is a valued supplier for complete solutions of tailor-made packing concepts. A highly effective machine program, handling and logistics components, uniform controls as well as the cooperation with experienced partners lead to optimal solutions which do not only convince by their cost effectiveness and flexibility.

Semi up to fully automatic master concepts thus optimize the complete packing process. The efficient use of manpower and automation, specific to the customers’ requirements, are most important. LIGMATECH convinces with innovative system and machine technology and provides intelligent packing solutions starting from batch size 1 up to serial production. And all that in a competent and reliable way and including comprehensive service: The complete solution from a single source.

Source: LIGMATECH Automationssysteme GmbH

Have something to say? Share your thoughts with us in the comments below.