West Chester, Ohio - Biofuels offer several advantages compared to traditional fuel sources. The advantages of biofuel are economic, environmental and practical. Biofuel can be produced from local sources of readily available material. Localized fuel reduces transport cost and CO2 emissions from transit. Further, Biofuels achieve CO2-neutral combustion and are suitable for automatic combustion (if suitably processed). The important challenge to biofuel availability is proper processing. Extensive drying is typically necessary to remove moisture from the organic material before use. The Drying Technology Department at Allgaier Process Technology GmH have addressed the unique process criteria of biofuel drying.

Advantage of Biofuel Drying

A wide variety of material can be used as a source of biofuel. Wooden pellets can be produced from wood chips, waste wood, green garden waste, bark, and rejected material from paper recycling. Other common organic materials are also used to create biofuels. Examples of organic materials used as biofuel include the fermented substrate of sugar beets, used coffee grounds, horse dung, straw, grass, bagasse and fruit pumice. Although the utilization of readily available and local organic materials is an advantage, there is energy variance each material provides as a fuel source. The below table displays the energy produced from several examples of biofuel. The table also provides a comparison to the apparent calorific value when drying the material before using it as biofuel. As shown, there are examples where drying the material can double or triple the apparent calorific value per kilogram of material.

| Material | Energy (moist) (kJ/kg) | Energy (dried) (kJ/kg) |

| Wood & Garden Waste | 6.3 | 14.65 |

| Bagasse | 9.2 | 18.4 |

| Fermentation from Domestic Waste | 16.7 | 18.9 |

| Straw | 10.05 | 10.5 |

Drying organic material

Biofuels can be economically advantageous, environmentally-friendly and achieve the high temperatures necessary to be a good source of fuel. In many cases, biofuels benefit from drying (as noted in the above table). Because the raw input material is often bulky and uneven, biofuels provide a challenge to processing and drying. In addition to the size and weight variance, there are several other variables involved with processing biofuel. Many biofuel sources have high levels of contamination, are sensitive to temperature and may emit volatile matter or explosive dust. These variables pose unique challenges to traditional methods of drying. Each type of traditional drying has a unique set of advantages and disadvantages.

Drum dryers (rotary dryers) are comparatively large machines which run gas parallel with the solids while drying. Although drum dryers have comparatively simple operation, drum dryers are capable of emitting fine material with a low “de-dusting” effect. Accessibility for maintenance may be limited.

Fluidized bed dryers provide perpendicular gas flow to the solid flow on a shallow bed. Fluidized bed dryers have demonstrated advantages when material is standard size. Often, biofuel materials have non-standard sizes. As a result, fluidized bed dryers can form “carpets” when drying bulky and fibrous products. Many organic materials can be bulky and fibrous, such as tree cuttings, which can stick to internal parts. Fluidized bed dryers can potentially enable the drying air to become saturated with moisture easily. Energy consumption can also be a factor.

Belt dryers also have perpendicular gas and solid flows (similar to fluidized bed drying). Belt dryers do solve the issue of potential “carpet” formation encountered by fluidized bed dryers. However, they can only be used for low-temperature drying and do not “de-dust” products. Further, belt dryers are limited in the ability to mix the product during drying. The product remains stationary relative to the other material during the process. As a result, the quality of dried material may be inconsistent.

A “Wish List” for Organic Material Dryers

By comparing the advantages and disadvantages of the current drying technologies, it is possible to create a list of ideal dryer characteristics:

• Ability to process a scope of different waste

• Deep bed of bulk material

• Long retention time

• Extensive mixing of the material

• Ability to run on waste heat (low heat/secondary heat)

• Low air velocities

• Low pressure drop

• Low electrical consumption

• Efficient “de-dusting” of the product

• Removal of impurities (sand, etc)

• Simple Design

• Acceptable overall dimensions

• Low weight for the moving/rotating parts

• Easy access for maintenance

Addressing the Challenge

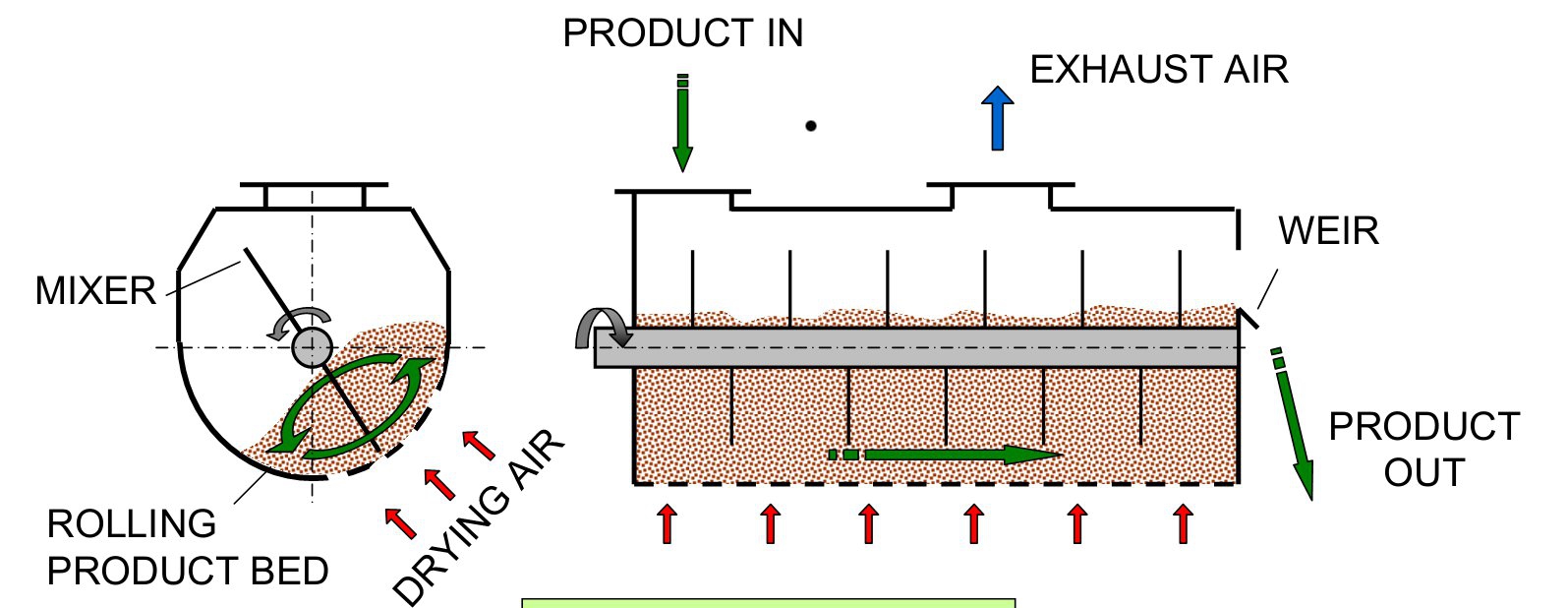

For organic drying, the ability to provide sufficient residence time for the material, prevent partial overheating of the material, ability to use secondary heat, prevention of poor solid mixing and heavy construction expense provide a combination of challenges to the traditional dryer technologies. The Dryer Technology team at Allgaier Process Technology GmH dedicated their extensive experience to developing a solution to meet the demanding criteria of organic drying. By combing features of fluidized bed drying with rotary drum drying, a hybrid dryer has been developed. Referenced as the Rolling Bed Dryer (WB-T), the dryer combines advantages of fluidized bed and rotary dryers. The WB-T dryer provides gentle drying at low temperatures which allows for high energy efficiency with thorough drying of organic materials.

Concept of Rolling Bed Dryer

The Rolling Bed Dryer combines attributes of the fluid bed dryer with the rotary drum dryer to provide gentle drying at low temperatures. The Rolling Bed Dryer (WB-T) has a compact bed for optimum heat exchange with a design that allows for long retention time with effective homogeneous drying of product. The Rolling Bed Dryer (WB-T) allows for an adjustable velocity of the drying air (to allow processing of different waste types). Tests on a WB-T dryer demonstrated a wet input material with 42% residual moisture (irregular sized material and bulk density of 160 kg per cubic meter) was converted to dry material with a residual moisture content of 4% (bulk density of 99.5 kg per cubic meter). Below is a cross-sectional view from the front and side.

Below is a chart outlining the drying of wood chips (Spruce/Pine). The product temperature is dependent on the drying air temperature. The retention time between 30 minutes and 2 hours is also dependent on drying air temperature. As shown, low temperature drying is possible (allowing for the use of waste/secondary heat to operate the process).

Drying of Wood Chips (Spruce/Pine)

Temperature of Product (Celsius)

Drying Time (Minutes)

Reference Plant Installation

The effectiveness of the Rolling Bed Dryer is demonstrated by the reference installation picture below (Topell Energy BV site – Netherlands)

Source: ALMO Process Technology

Have something to say? Share your thoughts with us in the comments below.