Check out some of the strategies used by the 2017 WOOD 100 companies to develop innovative products. This year's class includes cabinet and casework manufacturers, residential and office furniture producers, architectural woodworkers, store fixture manufacturers, wood component manufacturers, closet companies and more.

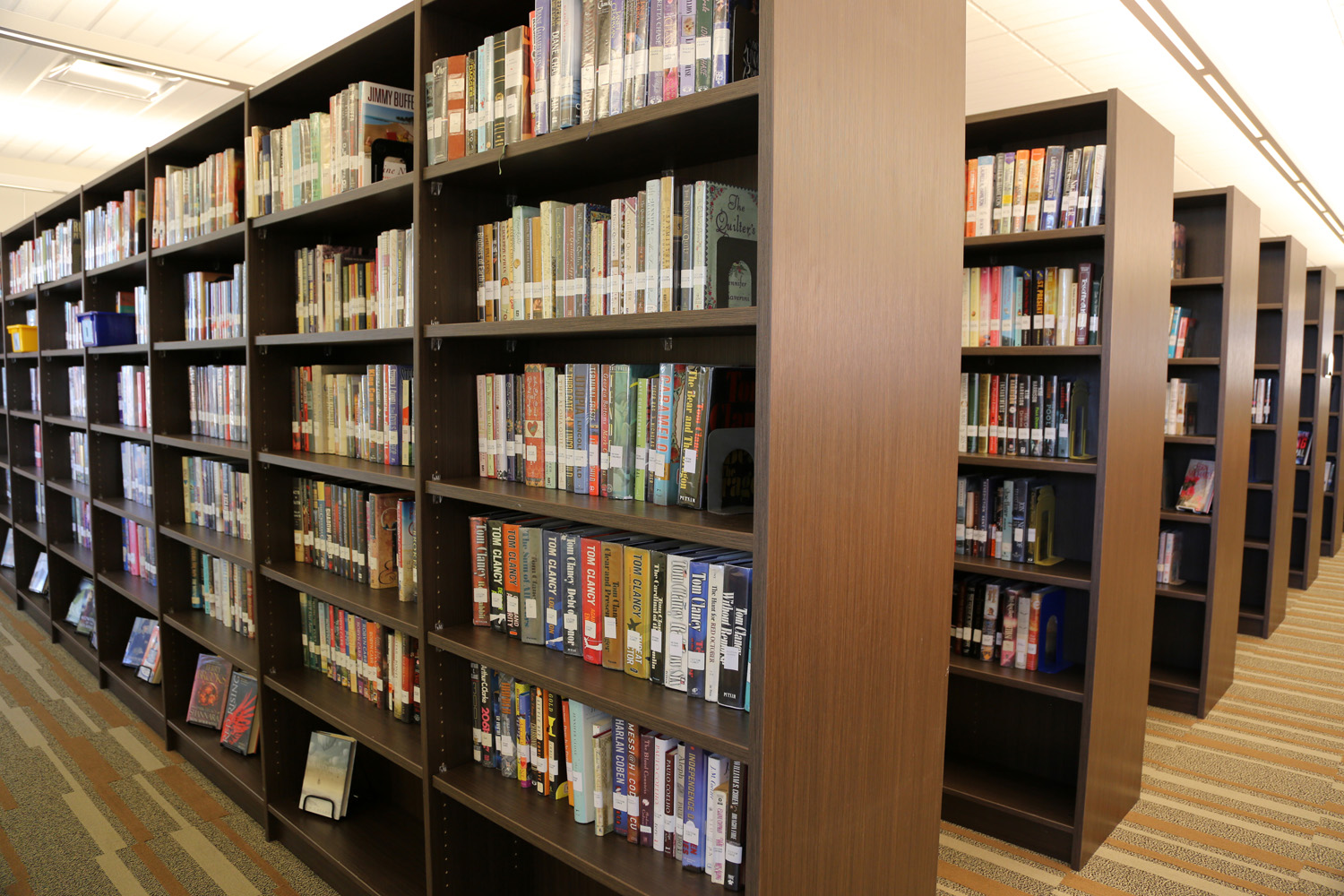

Stevens Industries, Teutopolis, IL — New product development, along with productivity enhancements, are driving up revenues at the commercial casework and millwork manufacturer.

Stevens Industries, Teutopolis, IL — New product development, along with productivity enhancements, are driving up revenues at the commercial casework and millwork manufacturer.

2016 sales were up 16.7%, and 2017 looks to be even better. “We’re focused on product innovation, and the exposure of those products and services to our customers,” said Amanda Emmerich, marketing coordinator. “Our growth depends on our customer’s ability to rely on us for innovative products delivered to their requirements.”

A facility expansion and new equipment purchases in 2017 will enhance productivity. A panel processor and TFL panel supplier, Stevens is a single site producer of commercial cabinetry, millwork, countertops and solid surface material, specializing in large scale projects. It also sub-contracts fabrication and assembly for private label products.

Bella Innovative Modern Cabinetry, Ft. Wayne, IN — The cabinetmaker’s production and sales strategies are opening new doors in the marketplaces. A division of Chadwick Industries, Bella IMC is among the first in the industry to incorporate Lockdowel fastening technology in its RTA cabinetry, sold nationwide through an online ordering system driven by Allmoxy.

Bella Innovative Modern Cabinetry, Ft. Wayne, IN — The cabinetmaker’s production and sales strategies are opening new doors in the marketplaces. A division of Chadwick Industries, Bella IMC is among the first in the industry to incorporate Lockdowel fastening technology in its RTA cabinetry, sold nationwide through an online ordering system driven by Allmoxy.

While similar to other fastening systems in that the connector fits into a connection point, what separates the Lockdowel snap-together system is that no glues, nails or clamps are needed.

“There was no doubt in my mind that this was a game changer for us,” said Chad Shelton, president of Bella IMC and Chadwick Industries. “We’ve invested over $750,000 and climbing to change everything to this system.”

The Bella IMC frameless cabinetry can be ordered online in customized sizes to 1/16 inch, assembled or ready-to-assemble. “We are always adding new cabinets to the ordering site,” Shelton said. Customers can order the cabinet box only, cabinetry components, or a complete cabinet, in a variety of door and drawer front styles. “This is a whole home product and can be used in all markets.”

More Top Products

JB Cutting Inc., Mt. Clemens, MI

A number of factors helped drive the custom component manufacturer’s 16.7% sales growth, noted Christina Relyea, sales & marketing manager, including “bringing on new colors to match what major TFL manufacturers were developing, and honing in on processes for increased efficiency and productivity.” The company also hired a business coach to focus on employee development. The company’s products are targeted to store fixtures, healthcare furnishing environments, residential kitchen and bath, and home storage.

Pure Timber LLC, Gig Harbor, WA

Owner Chris Mroz credited new product development, as well as cost controls to increase profit margins, for the company’s 2016 sales growth. Pure Timber makes curved solid bentwood parts for handrail, civic art installations, furniture, architectural fabrication, and musical instruments.

Signature Custom Cabinetry Inc., Ephrata, PA

“We put a strong focus on quality and overall performance, combined with aggressive product development and styling,” said Kent Martin, president/CEO in referencing the cabinet company’s 19.0% sales growth. It produces fully custom residential cabinetry for independent dealers and designers nationwide.

Norwalk Furniture, Norwalk, OH

The residential furniture maker is splash with its natural fabrics line. “While the many various brands and classifications of performance fabrics have surely been in the forefront of home furnishing for the last several years, designers and consumers continue to demonstrate a strong ongoing preference for natural fibers and fabrics with minimal chemical treatments and environmentally sensitive constructions,” said Dixon Bartlett, chief creative officer.

Trendway Corp., Holland, MI

The office furniture makers said its Confer benching system can accommodate fixed and stand-alone work surfaces, including perpendicular applications, in one layout. “When Trendway decided to create a benching offering, we approached it from the user’s point of view,” said Pete Phillips, director of product development.

Xybix Systems Inc., Littleton, CO

A maker of ergonomic, adjustable-height office furniture, Xybix’s sales grew 7.9% in 2016, due in part to its new product offerings. “We’re developing cleaner, more user-friendly products that maximize customer utility and overall value,” said Steven Holan, VP of operations. The firm also invested in a Buerkle 3D laminator and Biesse 5-axis CNC router to aid its production.

AB&D Furniture Mfg., Homewood, IL

Product development is credited for helping spur a 20.0% sales growth in 2016, said Christopher Agate, director of Design & Engineering. And 2017 should be equally as good for the wood and laminate contract furniture manufacturer. With its highly trained staff at the “45,000-square-foot, state-of-the-art facility, AB&D has the ability to accommodate small and large run projects,” he added.

Aitkin Hardwoods, Aitkin, MN

Division Manager Dave Schaefer credits “developing new products to fit changing market demands,” for helping the wood flooring and millwork producer drive sales. 2016 technology investments include an end matcher, gang ripsaw and moulder.

Read more 2017 WOOD 100: Strategies for Success

Marketing Initiatives

Go-to-Market Strategies

Business Strategies

Productivity Enhancements

Technology Integration

Product Innovations

Customer Service

Return to WOOD 100 Main Page

Read the special Leadership Edition of FDMC online

Have something to say? Share your thoughts with us in the comments below.