Wood can burn. That's obvious. Wood chips and pellets belong to the important secondary fuels category in modern power plants, furnaces or heat generators.

Wood can burn. That's obvious. Wood chips and pellets belong to the important secondary fuels category in modern power plants, furnaces or heat generators.

Yet it is still not common knowledge that this combustibility makes wood handling processes some of the most hazardous in industry from an explosion standpoint. Statistics about explosion incidents are evidence enough.

| Material/ Industry |

Explosion Ratio % |

| Wood | 27.9 |

| Paper | 1.3 |

| Coal | 10.5 |

| Food (flour, starch, etc.) | 26.7 |

| Plastics | 10.9 |

| metals | 12.9 |

| Other | 9.8 |

| Table 1: Ratio of Comdust Explosions by Industry |

|

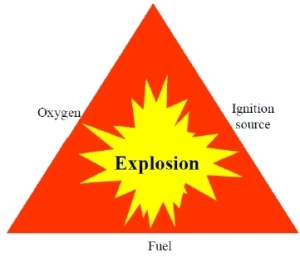

But what makes wood material and wood handling processes so special in terms of explosion hazards? This question can be answered quite simply, considering there are just three basic requirements of a dust explosion phenomenon:

• combustible dust

• air / oxygen

• effective ignitions sources

Nearly all wood handling installations have this “perfect mixture” for dust explosions to occur. Additionally, given mechanical moving parts as well as drying processes, ignition sources are easily generated.

In Autumn 2012, this deadly combination led to one of the most severe wood dust explosions in history in South America, where 5 people lost their lives and the entire plant was shut down for more than 5 months.

How to protect against explosion hazards in wood handling installations?

The explosion safety concept for such plants typically is made up of a combination of explosion prevention measures (to reduce the likelihood of explosion) and explosion protection measures (to reduce the effects of an explosion to an acceptable level).

Explosion Prevention means taking measures to prevent the formation of explosive dust clouds as well as avoiding ignition sources by dedusting, housekeeping, grounding, proper maintenance and/or spark extinguishers.

We know that even if all preventative measures are applied (especially with regard to the latter), this approach might lead to misapplication of spark extinguishers which

• might not work if particles are large;

• cannot suppress an explosion;

• are only addressing the ignition risk arising from small, hot particles; and

• do not prevent ignition sources from tramp metal or hot surfaces.

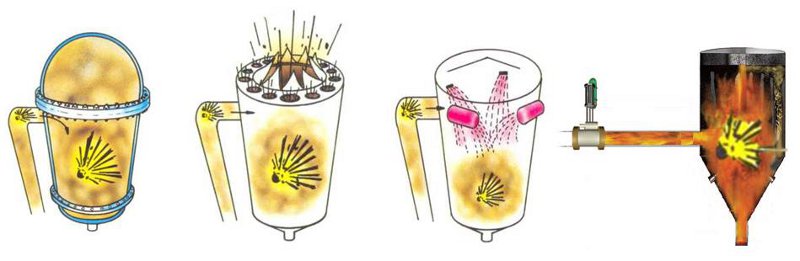

That is why protective measures also have to be applied in most wood handling installations. They typically apply one of three approaches:

That is why protective measures also have to be applied in most wood handling installations. They typically apply one of three approaches:

• explosion resistant design (simple explanation: make equipment so sturdy it will withstand explosion overpressure of up to 10 bar)

• explosion pressure venting (simple explanation: pressure and flame relief by applying a predetermined breaking point on the installation)

• explosion suppression and (simple explanation: a rapid fire extinguisher that stops the flame )

• plus: Explosion isolation (simple explanation: Prevent flame and/or pressure propagation to down or upstream units)

Due to minimal maintenance requirements and low investment costs, passive explosion protection approaches such as explosion pressure venting is the most commonly used in wood handling facilities. The fact that these burst panels can even be combined with flame-trapping mesh materials allows various applications to be protected by so called flameless vents.

As with any comprehensive safety concept, even a fully protected plant can only be secured when all relevant persons, situations and conditions are taken into account. In practice, this means that plant management in the wood handling industry has to be aware of the explosion risk in general, implement available explosion safety measures and educate plant personnel. The awareness of the need for combustible dust explosion safety has to be raised so that catastrophic events are not likely to endanger health, lives and business objectives such as profitability, continuity and productivity.

Therefore, a risk analysis should be carried out to identify the hazards and to allow the implementation of appropriate safety measures.

As an aside: The “butterfly” effect!

When conducting a risk analysis, all circumstances have to be taken into consideration – this last example impressively shows that even small “bugs” can influence the explosion risk of plants:

Several saw mill operators carried out a risk analysis and decided not to protect their installations that handle wood chips with normally high humidity content. These conditions changed following a pine beetle infestation that led to numbers of dead/dried trees. After a long period of quarantine, these trees were purchased at a low price and brought to the saw mill. Due to the pine beetle infestation, the resulting wood chips lots were drier than usual and many explosions occurred in the saw mill plants, lead to long downtimes and several injured people.

About the author: Johannes Lottermann Dr.-Ing Senior Consultant Explosion Protection; Head of Projects and Expansion Department, REMBE GmbH. Lottermann has spent most of his life studying, researching and developing new concepts and approaches to combustible dust explosion protection. In addition to his doctoral thesis, “Approaches to Integrated Fire and Explosion Safety…”, Lotterman has worked for notified bodies charged with certifying compliance with ATEX certifying requirements in Europe, governmental regulatory bodies equivalent to OSHA, standards associations equivalent to NFPA, as well as conducting risk analyses in manufacturing facilities.

Source: REMBE, a leader in the development and manufacture of cutting edge combustible dust explosion protection/prevention equipment and is the inventor of indoor flameless venting technology currently being used in many locations in the US and throughout the world.

Have something to say? Share your thoughts with us in the comments below.