Whether you’re trying to organize a production shop, garage shop, or your home, consider a modular cabinet design. It’s flexibility means you aren’t locked into a permanent arrangement of cabinets or their contents.

I am in the process of reorganizing the bench area of my shop and spent a lot of time thinking about how to go about it in a way that offered the most flexibility, ease of reconfiguring, and options for future expansion.

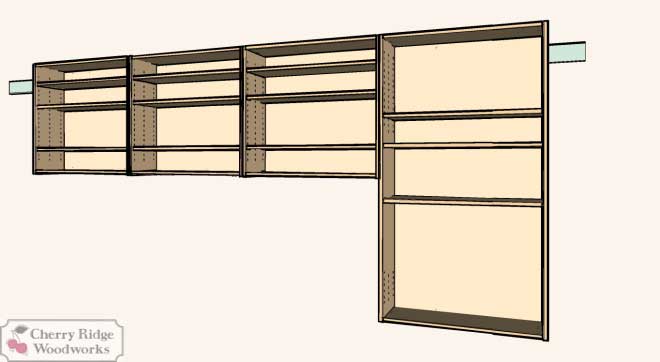

For my application, wall cabinets roughly 30-32″ wide and 32″ high would fit my space nicely. The cabinets would be a standard 12″ deep.

I decided to focus and start with one wall. The cabinets I would be building and installing aren’t permanently attached to the wall. Instead, they hand on a French cleat. So I ripped some 1×4 stock with a 45° bevel along one edge. I installed this cleat on the wall with the bevel up and facing the wall. A couple of long screws secured it at each stud location.

I decided to focus and start with one wall. The cabinets I would be building and installing aren’t permanently attached to the wall. Instead, they hand on a French cleat. So I ripped some 1×4 stock with a 45° bevel along one edge. I installed this cleat on the wall with the bevel up and facing the wall. A couple of long screws secured it at each stud location.

To make construction quick and easy, I cut the parts for the top, bottom, and sides of the cabinets the same length. Of course, you can modify the dimensions to suit your space and storage needs. I used 3/4″ plywood left over from previous projects. They’re shop cabinets, plus they’ll eventually have doors, so the mix of plywood didn’t bother me. Plus it’s a good way to use up project leftovers. The tops and bottoms of the cabinets are joined to the sides with pocket hole joinery. I didn’t feel the need to use glue.

The backs of the cabinets are a bit unique from conventional cabinetry because they’re 1/2″ thick. I used Baltic birch plywood.

The reason for the thicker back is twofold. I assembled the entire cabinet using pocket hole joinery. I used Kreg’s Micro-Pocket Drill Guide to drill the pocket holes spaced about every 6″ along all four edges of the back. The smaller pocket holes were more suited to the thinner stock. You can certainly use a standard or industrial pocket hole machine, but you’ll have to adjust for the stock thickness. The second reason for using a thicker back is that it allow for mounting custom tool holders or racks. In some of the cabinets, I plan on mounting racks for hand tools like screwdrivers and chisels. Layout tools like squares would fit on custom brackets.

The reason for the thicker back is twofold. I assembled the entire cabinet using pocket hole joinery. I used Kreg’s Micro-Pocket Drill Guide to drill the pocket holes spaced about every 6″ along all four edges of the back. The smaller pocket holes were more suited to the thinner stock. You can certainly use a standard or industrial pocket hole machine, but you’ll have to adjust for the stock thickness. The second reason for using a thicker back is that it allow for mounting custom tool holders or racks. In some of the cabinets, I plan on mounting racks for hand tools like screwdrivers and chisels. Layout tools like squares would fit on custom brackets.

Once everything is joined with pocket screws, I added a bracket at each upper corner of the back to engage the French cleat on the wall. They’re 6″ long and cut from the same 1×4 stock used to make the French cleat. At the bottom corners on the back, I added some 3/4″ kickers so the cabinet would sit plumb on the wall.

And that brings me to the doors. If you’ll notice on most 12″-deep cabinets, things get lost on the back of the shelves. So I plan on using narrow shelves and mounting some items on the inside of the doors. This makes everything in the cabinet easier to access.

As with any organizational project, it’s a work in progress. But the beauty of a modular design is that you can rearrange and move things without a lot of effort.

You can download and take a look at my SketchUp model of the cabinets and how they’re built.

Have something to say? Share your thoughts with us in the comments below.